From Challenging Well Water to Safe, Crystal-Clear Drinking Water: A Family’s Story

My name is Aleksandr Pavlov, and as a water treatment specialist, I’ve seen my share of tough well water cases. But this one stood out. I received a call from a family of four living in a suburban gated community. Their home, with its two bathrooms and numerous water-sensitive appliances, was suffering from the effects of a challenging combination of iron, manganese, hardness, and a hint of hydrogen sulfide — a rare case requiring whole house reverse osmosis for well water.

Water Analysis: Understanding the Problem

Before designing any treatment system, I always conduct a thorough water analysis. For this family, the results confirmed a serious challenge that required a multi-stage solution.

Key Contaminants Detected

Measured in standard American units (ppm, GPG, pH)

| Parameter | Value |

|---|---|

| Iron (Fe) | 3 ppm |

| Manganese (Mn) | 1 ppm |

| Water Hardness | 7 GPG |

| Hydrogen Sulfide (H₂S) | Trace (low concentration) |

| pH | 6.98 (nearly neutral) |

| Total Dissolved Solids (TDS) | 760 ppm |

The combination of iron, manganese, moderate hardness, trace hydrogen sulfide, and relatively high TDS presented a complex challenge. Each contaminant required careful consideration to protect both the family’s health and the longevity of their appliances. This analysis formed the foundation for a custom multi-stage water treatment solution, including mechanical filtration, multimedia tanks, reverse osmosis, and controlled remineralization.

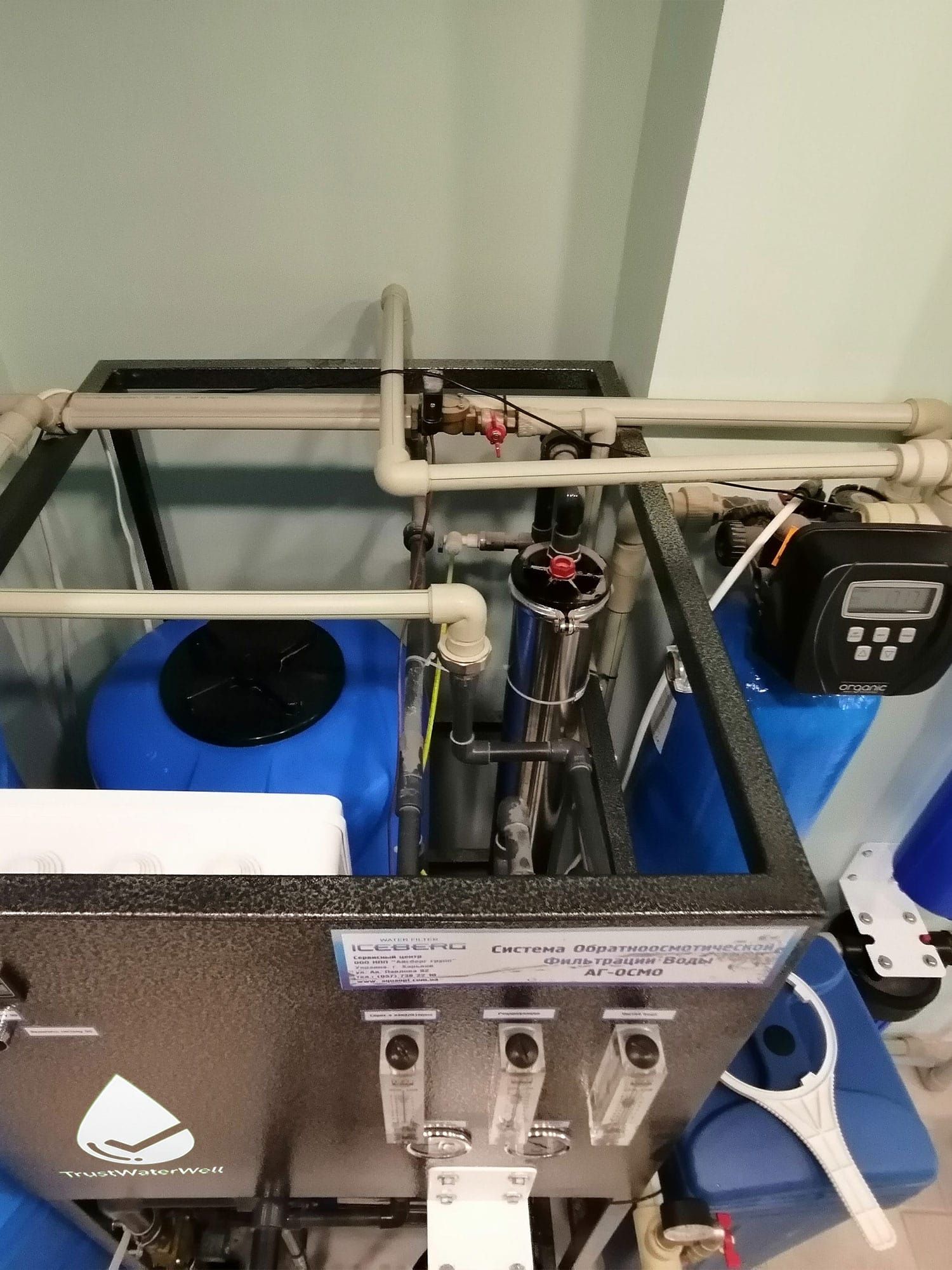

A system for a factory? Nope — it’s for a home!

At that time, we rarely installed commercial-grade whole-house reverse osmosis systems, but this case highlighted the need for a multi-barrier approach. While the home’s plumbing avoided metal components that could corrode from pure RO water, I still arranged a controlled remineralization step to ensure the water was safe, balanced, and enjoyable for daily use.

Interestingly, installing a full-house reverse osmosis system was not strictly necessary. Standard multimedia column filters could have easily removed the iron, manganese, and hardness, producing water that was not only clean but also naturally remineralized with safe, healthy minerals and salts.

However, the family was accustomed to the exceptional purity of RO-treated water. They had previously lived on the seashore, where their well water was slightly salty, and there they had successfully used a reverse osmosis system to achieve perfectly clean, soft water. Having grown used to this level of quality, they specifically requested the same experience in their new home. Respecting their preference, we designed and installed a whole-house RO system that delivered the ideal balance of purity, taste, and safety while incorporating a controlled remineralization step to protect both health and plumbing.

A Whole House Reverse Osmosis System for Well Water

To tackle the complex combination of iron, manganese, hardness, trace hydrogen sulfide, and high TDS in a home of four people with two bathrooms and sensitive appliances, we designed a comprehensive, multi-stage water treatment system. Each stage was carefully engineered to protect the household, ensure optimal taste, and provide reliable performance over years of operation.

Equipment Overview

All key components used in the system with technical details

| Step | Component | Purpose / Technical Notes |

|---|---|---|

| 1 | Big Blue 20″ Polypropylene Sediment Cartridge | Removes sand, silt, rust; melt-blown graded porosity 50–5 µm; protects downstream media; replace 6–9 months |

| 2 | Multimedia Column – Multicomponent Ion-Exchange (37 L) | Cationic resins layered: strong acid, weak acid, Fe/Mn-specific; system is regenerated with NaCl brine using a Clack WS CI control valve; flow 3–4 GPM; removes Fe²⁺, Mn²⁺, hardness; |

| 3 | Commercial-Grade RO Skid, 250 L/hr | Thin-film composite membranes, 400 GPD; removes 99% TDS; feed 760 ppm TDS; pH 6.98; pressure 120–150 PSI; pre-filters protect membranes |

| 4 | 1000 L Atmospheric Tank | Stores treated water; partial H₂S venting; balances household demand |

| 5 | Grundfos Intelligent Booster Pump | Maintains constant >50 PSI; variable-speed; supports two bathrooms and appliances simultaneously |

| 6 | Ultraviolet (UV) Sterilizer | Disinfects water by inactivating bacteria, viruses, and protozoa; stainless steel chamber; 30 mJ/cm² dose; no chemical residues |

| 7 | Activated Carbon Post-Filter, Catalytic Coconut Shell | Final H₂S removal; odor and taste improvement; 5 µm; replace 9–12 months; steam-activated catalytic carbon with enhanced surface for breaking down chloramine and sulfur compounds |

Step 1: Mechanical Pre-Filtration

Big Blue 20″ Polypropylene Sediment Cartridge

The first line of defense is a robust 20-inch sediment filter with a polypropylene cartridge.

Manufactured via melt-blown extrusion, the fibers are layered to form a graded porosity from 50 µm to 5 µm, effectively capturing:

- Sand

- Silt

- Rust

- Other particulates

This design minimizes pressure drop while protecting all downstream components — especially RO membranes — from clogging or premature wear.

Flow capacity: 20 GPM

Replacement interval: every 6–9 months (depending on turbidity)

Step 2: Comprehensive Contaminant Removal – Multicomponent Ion Exchange

Multimedia Column, 37 liters, stacked ion-exchange resins

This stage removes iron (3 mg/L), manganese (1 mg/L), reduces hardness (7 GPG), but is not effective against hydrogen sulfide, which is removed in later stages. The column contains 37 liters of layered ion-exchange media, specifically designed for a full-house load:

- Bottom layer: Strong acid cation resin (spherical, 0.5–1.2 mm), removes calcium and magnesium ions (hardness).

- Middle layer: Manganese greensand-type resin or weak acid cation resin, targeted removal of Mn²⁺ ions through ion exchange.

- Upper layer: Iron-specific cation resin, removes Fe²⁺ ions converting them into removable form.

- Top layer: Filtration gravel to evenly distribute flow and prevent channeling.

Chemical mechanism: Fe²⁺ and Mn²⁺ replace H⁺ ions on cationic resin sites. Regeneration occurs with NaCl solution (brine) every 4–6 weeks depending on household consumption (~4 m³/day). The column is sized to provide flow of 2–3 GPM for a family of 4 with dual bathrooms and high-efficiency appliances. Pressure drop across column: 8–12 psi at design flow.

This stage prepares water for reverse osmosis while ensuring long-term protection of all downstream components.

Note: The exact types and arrangement of resins are selected by the original manufacturer and are not disclosed in detail.

Step 3: Whole-House Reverse Osmosis

Commercial-Grade 250 L/hr RO Skid, membrane: 400 GPD, polyamide thin-film composite

Reverse osmosis removes up to 99% of dissolved solids — salts, nitrates, and trace metals.

Membrane specs:

• 400 GPD (~1.5 m³/day)

• Operating pressure: 120–150 PSI

• Feed pH: 6.8–7.0

• Feed TDS: 760 ppm

Membranes are protected with 5 µm pre-filters and require periodic flushing every 6–12 months.

Note: Hydrogen sulfide is not removed chemically, though odor decreases after storage in the tank.

Step 4: Storage Tank

1000 L Atmospheric Tank

Treated water is stored in a 1000-liter atmospheric tank. During storage, hydrogen sulfide partially dissipates naturally. The tank ensures a constant supply for 4 occupants, balancing demand across two bathrooms and multiple appliances.

Step 5: Pressure Boost

Grundfos Intelligent Booster Pump

Ensures consistent water pressure (>50 PSI at taps) throughout the house. Automatic variable-speed pump responds to simultaneous water draw from two bathrooms and appliances, maintaining flow without stressing membranes or piping.

Step 6: UV Disinfection

Ultraviolet Sterilizer, 30 mJ/cm² dose, stainless steel chamber

This step ensures microbiological safety by using a UV-C ultraviolet lamp (wavelength: 254 nm) to inactivate bacteria, viruses, and protozoa.

The UV unit delivers a minimum dose of 30 mJ/cm², effectively destroying >99.99% of common waterborne pathogens — without any added chemicals.

- Stainless steel chamber — improves reflectivity and durability

- Quartz sleeve — ensures high UV transmission

- Annual lamp replacement is recommended

Step 7: Final Polishing & Hydrogen Sulfide Removal

Activated Carbon Post-Filter, Coconut Shell, 5 µm

Removes residual H₂S, chlorine, and organic compounds. The filter uses catalytic coconut-shell activated carbon with 5 µm porosity.

Manufactured via steam activation and catalytic surface modification, the carbon features:

- High microporosity

- Reactive surface area > 1000 m²/g

Unlike standard GAC, catalytic carbon doesn’t just adsorb — it actively breaks down resistant contaminants like chloramine and hydrogen sulfide through surface-driven redox reactions.

This is a physical surface modification, not a chemical additive process.

Ideal for well water and post-RO polishing. Recommended replacement: every 9–12 months.

This multi-stage water treatment system ensures a family of four enjoys perfectly clean, safe, and great-tasting water throughout the home. Every stage—from mechanical pre-filtration, multicomponent ion-exchange for iron, manganese, and hardness, whole-house reverse osmosis, to storage, pressure boosting, and activated carbon post-filtration—is carefully engineered. Children, sensitive appliances, and plumbing are fully protected, while TDS, H₂S, Fe, Mn, and hardness are reliably controlled. This expert-level system demonstrates how a detailed, scientific approach to water treatment ensures both safety and comfort in everyday life.

The Results: Pure, Safe, and Refreshing Water

After commissioning the system, the follow-up water analysis confirmed the complete transformation. The water became crystal clear, odor-free, soft, and perfectly balanced for a family of four. This whole house reverse osmosis system for well water successfully removed:

Water Analysis After Treatment

Final water parameters confirming effectiveness

| Parameter | Before | After | Safe Range (US) |

|---|---|---|---|

| Iron (Fe) | 3.0 mg/L | <0.1 mg/L (Not Detectable) | <0.3 mg/L |

| Manganese (Mn) | 1.0 mg/L | <0.01 mg/L (Not Detectable) | <0.05 mg/L |

| Water Hardness | 7 GPG | <1 GPG (Soft) | 0–7 GPG (Soft–Moderate) |

| Hydrogen Sulfide (H₂S) | Trace | 0 ppm (Not Detectable) | 0 ppm (Odor-Free) |

| Total Dissolved Solids (TDS) | 760 mg/L | 35 mg/L (Ultra-Pure) | 50–500 mg/L |

| pH | 6.98 | 7.0–7.2 | 6.5–8.5 |

Impact on Home and Family

- Crystal-clear, soft, and great-tasting water for drinking and cooking.

- No more stains or discoloration on sinks, showers, and appliances.

- Protection for sensitive household equipment, including washing machines, dishwashers, and water heaters.

- Safe and healthy water for children and adults.

- Reliable water flow and pressure throughout the house, with consistent quality from every faucet.

This whole-house water treatment system successfully removed iron, manganese, hardness, TDS, and hydrogen sulfide from the well water. The family now enjoys water that is not only safe and healthy but also aesthetically perfect—clear, odor-free, and soft. The system protects all household appliances, supports the family’s lifestyle, and ensures peace of mind knowing the water quality meets or exceeds US safety standards.

Maintenance & Costs: What You Can Expect

The system is designed for a family of four, providing consistent, high-quality water while minimizing maintenance effort and ensuring predictable annual costs.

Maintenance Schedule & Costs

Typical replacement intervals and estimated annual expenses

| Component | Replacement / Frequency | Estimated Annual Cost (USD) |

|---|---|---|

| Big Blue 20″ Sediment Filter | Every 6 months | $50–$70 |

| Multimedia Column (Iron/Manganese/Hardness) | Media refreshed every 3–5 years | $100–$150 per year (amortized) |

| RO Membrane | Every 2–3 years | $200–$250 per year (amortized) |

| Activated Carbon Post-Filter | Every 12 months | $80–$100 |

| Grundfos Booster Pump & System Check | Annual inspection | $50–$75 |

| Salt for Softener Regeneration | Approx. 600 lbs/year (~10 lbs per 6 days) | $360 |

Family & System Considerations

- Designed for 4–5 people with normal household consumption.

- Maintenance is straightforward: periodic filter changes, RO membrane replacement, and softener salt replenishment.

- Estimated yearly maintenance cost including salt: $840–$1015.

- Proactive maintenance protects appliances and prolongs system lifespan.

Regular maintenance of the whole-house water treatment system is simple and cost-effective. With clear schedules for sediment filters, RO membranes, multimedia media, activated carbon cartridges, and softener salt replenishment, a family of four can enjoy pure, soft water with predictable annual expenses. Proper upkeep ensures the system continues to remove iron, manganese, hardness, and hydrogen sulfide effectively, while protecting all household appliances and plumbing.